The TS-1000 fully automatic vacuum tray-sealing machine provides fast, economical and versatile packing

in high quantities in a short period of time with vacuum, gas flushing (MAP) or only simply sealing.

If high volume has to be packed this is the right machine for you. Simply load the filling trays onto the in-feed conveyor, the rest is done automatically by the TS-1000. The trays are transported out of the machine after packing and can be labelled and weighed afterwards.

| Technical detail: | ||

| Pump Busch (cbm/h): | 63 | |

| Maximum tray dimension: | 370 x 350 x 120 mm | |

| Top film width: | 422 mm | |

| Max. diameter of top film: | 330 mm | |

| Film core: | 76 mm | |

| Voltage: | 400/3Ph+N+PE/50HZ,25 Amp, 8 kW | |

| Power (kW): | from 4 | |

| Compressed air consumption: |

approx. 50 ltr./cycle at 6 bar |

|

| Speed: | 6 cycles per minute, 360 cycles per hour | |

| Loading station: | 1.250 mm with 3 open spaces | |

| Loading hight: | 950 mm | |

| Height of exit conveyor: | 950 mm | |

| Outer dimensions: | 3100 x 990 x 1950 mm | |

| Weight: | approx. 1000 kg |

Standard equipment

Options

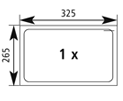

Standard trays:

1/2 gastronorm single tool

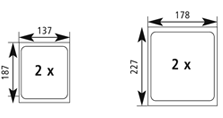

Trays:

double tool

The TS-1000 fully automatic vacuum tray-sealing machine provides fast, economical and versatile packing

in high quantities in a short period of time with vacuum, gas flushing (MAP) or only simply sealing.

If high volume has to be packed this is the right machine for you. Simply load the filling trays onto the in-feed conveyor, the rest is done automatically by the TS-1000. The trays are transported out of the machine after packing and can be labelled and weighed afterwards.

| Technical detail: | ||

| Pump Busch (cbm/h): | 63 | |

| Maximum tray dimension: | 370 x 350 x 120 mm | |

| Top film width: | 422 mm | |

| Max. diameter of top film: | 330 mm | |

| Film core: | 76 mm | |

| Voltage: | 400/3Ph+N+PE/50HZ,25 Amp, 8 kW | |

| Power (kW): | from 4 | |

| Compressed air consumption: |

approx. 50 ltr./cycle at 6 bar |

|

| Speed: | 6 cycles per minute, 360 cycles per hour | |

| Loading station: | 1.250 mm with 3 open spaces | |

| Loading hight: | 950 mm | |

| Height of exit conveyor: | 950 mm | |

| Outer dimensions: | 3100 x 990 x 1950 mm | |

| Weight: | approx. 1000 kg |

Standard equipment

Options

Standard trays:

1/2 gastronorm single tool